Welcome to CncToolsChina.com!

Welcome to CncToolsChina.com!

Cart

CloseYour shopping cart doesn't have any products yet!!

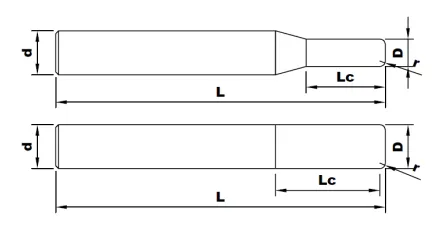

| Product Name | Solid Carbide Endmill CNC Cutter Tool For Metal |

| Material | Tungsten Carbide,Solid Carbide,Cemented Carbide |

| Product Type | Solid Carbide End Mills |

| Flutes | 1/2/3/4/5/6 Flutes |

| Coating | Altin, Tialn, Tisin, Tin, DLC,Nano, Diamond |

| Helix Angle | 10degree,15degree,25degree,35degree,45degree,55degree |

| Size | Metric & Inch Size Based On Your Requirement |

| Tolerance | h6 |

| Suitable For | Steel, Stainless Steel, Aluminum,Die Steel, Mould Steel, Carbon Steel, Cast Iron, Copper, etc. |

Efficient Cutting: The four-flute design allows four cutting edges to engage simultaneously during rotation, significantly enhancing cutting efficiency. Additionally, roughing end mills are typically used to remove large amounts of material, making the four-flute design ideal for rapid roughing tasks.

Improved Heat Dissipation: Multiple cutting edges distribute heat, reducing the risk of overheating. This helps maintain tool rigidity and accuracy while extending tool life.

Balanced Stability: The four-flute design ensures smoother and more stable operation at high speeds, minimizing vibrations and deviations, thereby improving machining accuracy.

Suitable for Heavy-Duty Cutting: Roughing end mills are often used for processing hard materials or scenarios requiring the removal of significant amounts of material. The four-flute design can withstand heavier cutting forces, making it suitable for heavy-duty cutting applications.

Cost-Effective: Due to its efficient cutting capabilities and suitability for various materials, the four-flute roughing end mill offers high value for money in industrial production, making it a commonly used tool in many machining centers.

Easy to Sharpen and Maintain: The four-flute design facilitates easier sharpening and maintenance of the tool. When one cutting edge wears out, it can be easily sharpened without the need to replace the entire tool.